Huayu Wantong The complete set of 6FSMCT series millet processing equipment designed and constructed can process japonica millet, glutinous millet, yellow millet, white millet, green millet, black millet and fragrant millet. The finished millet has high yield, good color and no impurities, which can meet the market demand and create high economic value for customers. The whole set of equipment optimizes all kinds of millet special processing equipment and special processing technology, develops new special shelling and peeling equipment, realizes intelligent operation, has strong specificity, reasonable layout, low power consumption, high yield, and good quality of finished products, and is widely used in food processing enterprises and grain processing enterprises. The core equipment has won national patents.

Performance characteristics

01 Complete set of special millet processing equipment adopts millet special processing equipment and special processing technology

02 Low energy consumption The energy consumption of complete millet processing equipment is 20% - 30% lower than that of the industry, and the dust removal of the production line meets the requirements

03 Different varieties use different equipment. Complete millet processing equipment has developed husking, hulling and rice making processes for different millet varieties in different regions at home and abroad

04 The complete set of millet processing equipment with low crushing rate selects the patented Huayu Wantong millet sand roller peeling machine and polishing machine, which can ensure the peeling effect and reduce the crushing rate according to the millet characteristics

05 High quality millet grading New grading equipment is used to effectively distinguish broken rice from intact rice and improve the quality of finished products

06 Add cold shutdown equipment in the complete set of millet processing equipment process to lock the nutrient content, prevent the loss of oil and denaturation of oily millet due to temperature rise, and lock the nutrient content without loss

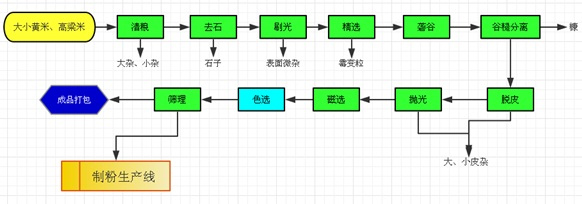

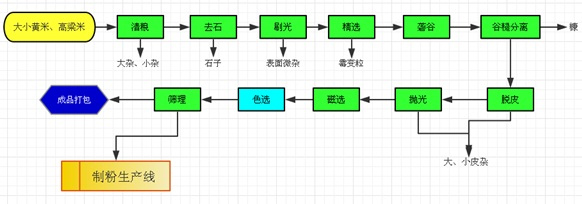

working principle

The millet processing complete set of equipment adopts special millet peeling and polishing equipment, clearly distinguishes the processing technology and clearly positions the processing equipment, and has developed rice hulling, peeling and rice making processes for different millet varieties in different regions at home and abroad. The energy consumption is 20% - 30% lower than that of the same industry. All cleaning equipment shall be subject to air suction treatment to make the equipment in a negative pressure state, so as to ensure that the ash does not spill out, ensure the environmental sanitation of the workshop, and the dust removal of the production line meets the requirements.

1. High stone removal precision: according to the material characteristics of millet, the refined stone removal machine is selected for the stone removal part. Compared with ordinary stone remover, it can more effectively remove the fine stones and sand contained in millet, and the stone removal accuracy can reach more than 98%;

2. Reduce the crushing rate: Huayu Wantong millet sand roller peeling machine with patent is selected. According to millet characteristics, it can not only ensure the peeling effect, but also reduce the crushing rate;

3. Improve the quality of finished products: The patented Huayu Wantong polishing machine and new grading equipment are selected for millet polishing and grading, which can effectively separate broken rice from intact rice. The pure kernel is polished by the polishing machine to remove the impurities on the kernel skin, increase the surface gloss, further increase the purity of kernel, and improve the quality of finished products.

4. Lock nutrients: cold shutdown equipment is added in the process to prevent oil loss of oily millet and denaturation due to temperature rise, and lock nutrients without loss.

technical parameter

| model |

Equipped with power (kw) |

Consumption per ton of material (kw/h) |

Output (t/24h) |

Plant size (lxwxh/m) |

| 10t |

thirty-two |

52-54 |

ten |

7x4x4 (linear structure) |

| 20t |

sixty-four |

52-54 |

twenty |

10x5x5 (linear structure) |

| 30t |

ninety |

50-52 |

thirty |

14x5x5 (linear structure) 10x5x7.5 (steel frame structure) |

| 50t |

one hundred and forty-two |

46-48 |

fifty |

16x5x5 (linear structure) 10x5x7.5 (steel frame structure) |